In commercial printing, ink is one of the main consumables that can be managed to potentially reduce costs. All commercial printing managers are looking for ways to control this cost. This applies to industrial inkjet printing as well as analog printing, like flexo printing or offset printing.

Applying only the precise amount of ink necessary to produce your required printing results is the obvious way to save on this budget line item, but there are additional and residual benefits that also impact and improve the bottom line for industrial printers.

The Cost Benefits of Using Less Ink

There are many additional benefits of reducing ink usage that also improve the bottom line, including some ways to achieve savings that apply to industrial inkjet printing and other commercial printing systems.

Kao Collins Inkjet Inks Reduce Downtime

Download

Shorter Drying Time

Less ink on the substrate leads to shorter drying times. That’s especially important if using an external ink curing system such as LED-light or UV-light. These savings add up to less energy use and increased life of the lighting system. The same is true for heat curing systems.

Higher Production Speed

Production managers have to sacrifice production speed to ensure the substrate has cured completely. With less ink used and shorter drying time, print jobs can be completed faster. That creates greater printing capacity or reduced labor costs.

Less Ink Optimizes Quality

While it seems counterintuitive, using less ink through optimization can improve printing results. The reality is that too much ink can negatively impact quality as much as too little ink.

Dot Gain

Before ink completely cures, the ink dots spread out. Optimizing for dot gain can reduce ink usage and improve quality.

The preparation of image files must account for the type of substrate being used and ink to compensate for dot gain, which is more pronounced on porous substrates. Dot gain, or tone value increase (TVI) is the spread of the ink in the halftone dots as the ink is absorbed. Color profiles for different substrates account for the expected dot gain. Too much ink will make the printed image look darker than intended because light is not reflected from the “white space” between the dots.

Bleed Through

Beside the negative effect of dot gain on image quality, too much ink on the substrate can result in bleed through. In the case of thin, porous substrates, printing with too much ink can impact the reverse side of the printing material when the ink is absorbed.

The Environmental Benefits of Using Less Ink

See Our Eco-Friendly Inks

Get Started

As more brands look to reduce their environmental impact because of increasing regulation and consumer demand, they are turning to their suppliers to contribute to sustainability efforts.

For inkjet printing, less ink consumption reduces the natural resources needed to produce the ink, the number of cartridges used and the energy needed during printing. All of this contributes to the sustainability of inkjet printing, reducing its environmental impact and increasing cost savings throughout the supply chain.

How to Optimize Ink Usage for Savings

Added together, the combination of actions can lead to 20-30% reduction in ink consumption.

Choose the Right Printing Resolution

It may be tempting to use the highest resolution the printer can deliver. Just because a printhead can lay down ink at 600 dpi it doesn’t mean it is necessary. In the case of barcodes and matrix codes, high resolution may be necessary to avoid scanning errors, but other jobs may only require a significantly lower resolution. That’s where dot gain can work to your advantage. Only use the resolution necessary to achieve the quality needed by the customer. Digital inkjet printing offers the distinct advantage of testing samples to determine the best results because there are no costly prepress expenses of plates.

Replacing neutral color tones with the black ink in CMYK printing reduces the amount of ink in the image.

Choose Gray Component Replacement

Black ink is your friend. When printing four-color (CMYK) projects, ink consumption can be drastically reduced. Rather than creating gray tones with trichromatic colors layers of cyan, magenta and yellow inks, the black ink in CMYK can often achieve the same result.

An added benefit is greater edge definition. Unless it is absolutely necessary to have the richest black tonal range, GCR can deliver significant savings.

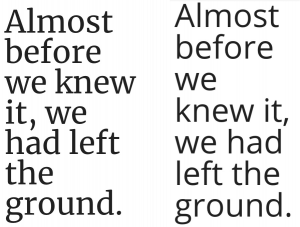

A Serif typeface on the left could consume more ink than a san-serif typeface on the right. Serif fonts feature the extra strokes on the letters.

Use ‘Eco-fonts’ for Typography

Consult with the designer to identify fonts that can reduce ink consumption. A client may require specific typefaces to maintain brand identity, but there may be opportunities to reduce ink consumption with an “eco-font” for some print jobs where those branded typefaces may not be necessary.

Light-face fonts and sans-serifs fonts can deliver incremental ink savings, especially on larger jobs such as transactional documents. When evaluating the impact of choosing a different typeface, be sure to consider the readability of the text.

Other Steps for Conserving Ink

Take Care of Your Printheads

Industrial printing inks with a short decap can result in wasted ink. When the ink dries in the printhead, purging and cleaning wastes ink. This is especially problematic for TIJ printing with solvent ink, which has notoriously suffered from short decap times. Kao Collins has solved that problem with the revolutionary SIGMA solvent ink. Its 12-hour decap time far exceeds any other solvent inkjet ink.

Use Original Print Cartridges

All the initial savings of using non-original cartridges can be lost when these cartridges fail, and you’re left with ink inside that can’t be used. That’s one reason Kao Collins packages inks for HP and Funai industrial printing systems in original, factory-new cartridges.

Install Bulk Ink Systems

Small amounts of ink remaining in single cartridges adds up during the production cycle. Bulk supply systems reduce unused ink. Bulk systems also increase efficiency.

Data Drives Decisions

Carefully tracking the yield of cartridges or bulk ink delivery helps you analyze the steps you’re taking to reduce ink consumption and overall production. Choosing the right ink for the substrate is equally important for achieving optimum quality and production efficiency.

Contact the Kao Collins technical team to discuss the inks available for best performance.

Frequently Asked Questions

How to use less ink when printing?

There are numerous methods of reducing the amount of ink used during printing.

- Emptying ink cartridges completely rather than at scheduled intervals.

- Use in packaged in factory-new cartridges

- Maintain printheads

- Lower inkjet print resolution to the lowest DPI necessary

- Choose a sans-serif font

- Use gray-component replacement

What is Gray Component Replacement?

It is the pre-printing process for preparing images and artwork for CMYK printing to use black ink for neutral tones instead of the combination of cyan, magenta, and yellow inks.

What is under color removal?

The CMYK pre-printing process for images removes cyan, magenta, and yellow inks in dark neutral (gray) areas, replacing the colors with full black.